We are delighted to announce that we have received a positive recommendation from BSI following our stage 2 assessment in relation to ISO 14001. Under the scope of the design, manufacture, and distribution of single use sterile and non-sterile plastic-based products, we were thrilled with the recommendation.

We invite you to embark on the journey as we share our initiatives, innovations, and progress toward fostering a more conscientious attitude in the med-tech industry.

- We are working towards Net Zero by 2045

- We are commencing an environmental product review programme to strategically move forward with product carbon reductions

Lean Practices, rooted from the Toyota Production System, are a set of principles and techniques designed to eliminate waste, optimise efficiency, and promote a culture of continuous improvement. At Pennine, we have integrated these practices into our daily operations, streamlining processes, and enhancing the value we deliver to our customers and partners.

We are not just a medical manufacturer; we are on a continuous journey towards excellence for the benefit our customers, suppliers, colleagues and the planet. Therefore, our commitment to delivering high quality medical devices is intertwined with our adoption of Lean Practices.

The Medical manufacturing industry demands precision, reliability, and uncompromising quality. Embracing Lean Practices enables us to meet these rigorous standards while achieving operational excellence. By starting to minimise waste and reduce lead times, we are continuing to champion UK manufacturing.

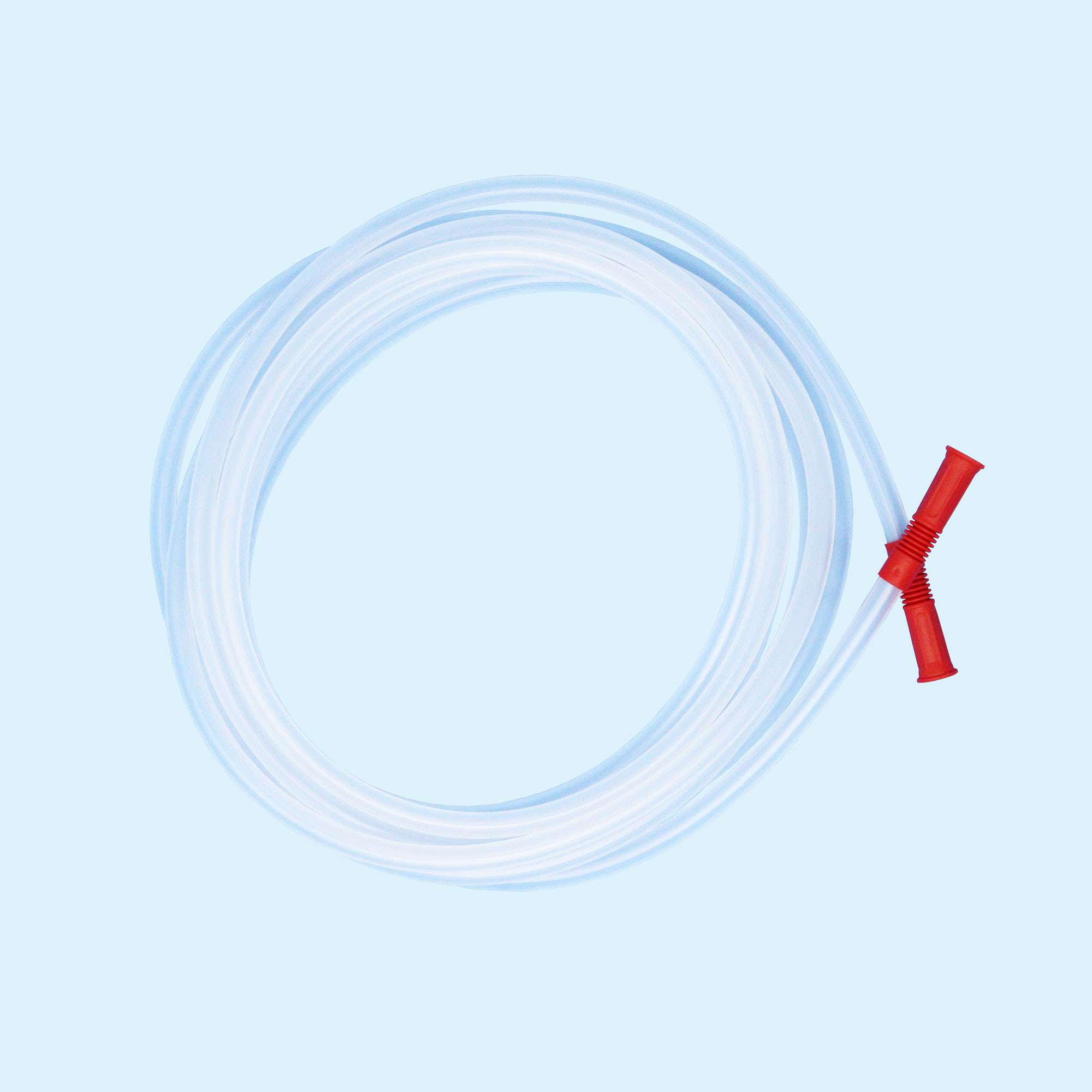

We are excited to announce our brand-new PVC-free medical device range, featuring innovative, polyolefin-based Thermoplastic Elastomer (TPE) products. Our commitment to advancing sustainable healthcare solutions drives our decision to adopt TPE, which can offer significant clinical and environmental benefits. First in our new range includes Non-Sterile and Sterile Suction Connecting Tubing.

Our polyolefin-based TPE compound is an ideal PVC alternative due to its robust physical properties and low CO2 impact. Made in Europe with 100% renewable wind energy, this compound is produced sustainably, with all waste being recycled. It’s durability and flexibility ensure excellent kink resistance and low friction for smooth fluid movement, whilst offering exceptional transparency for fluid flow monitoring. These features make it a highly effective choice for medical devices and is why we have opted for TPE as our PVC-alternative for Suction Connection Tubing.